**Enhancing Cathodic Protection in Deepwater Operations: Innovation in Brazil**

In recent years, the oil and gas industry has faced significant challenges in maintaining the integrity of subsea infrastructure. One major issue is the efficient monitoring of cathodic protection (CP) systems, which are crucial for preventing corrosion in underwater structures. Offshore Brazil, a region known for its deepwater and ultradeepwater oil production, is at the forefront of technological advancements aimed at optimizing and reducing the cost of CP systems.

**The Challenge of Traditional CP Monitoring**

Traditional methods for monitoring CP systems involve the use of divers and remotely operated vehicles (ROVs) fitted with CP probes. These probes need to physically touch the pipeline or structure to obtain readings, which can be slow, costly, and risky, particularly in deepwater environments. The limited accuracy and efficiency of these methods can lead to missed issues such as coating damage or unexpected anode depletion rates, posing significant safety and longevity risks to the subsea infrastructure.

**Introducing FORCE Technology’s FiGS: Revolutionizing CP Monitoring**

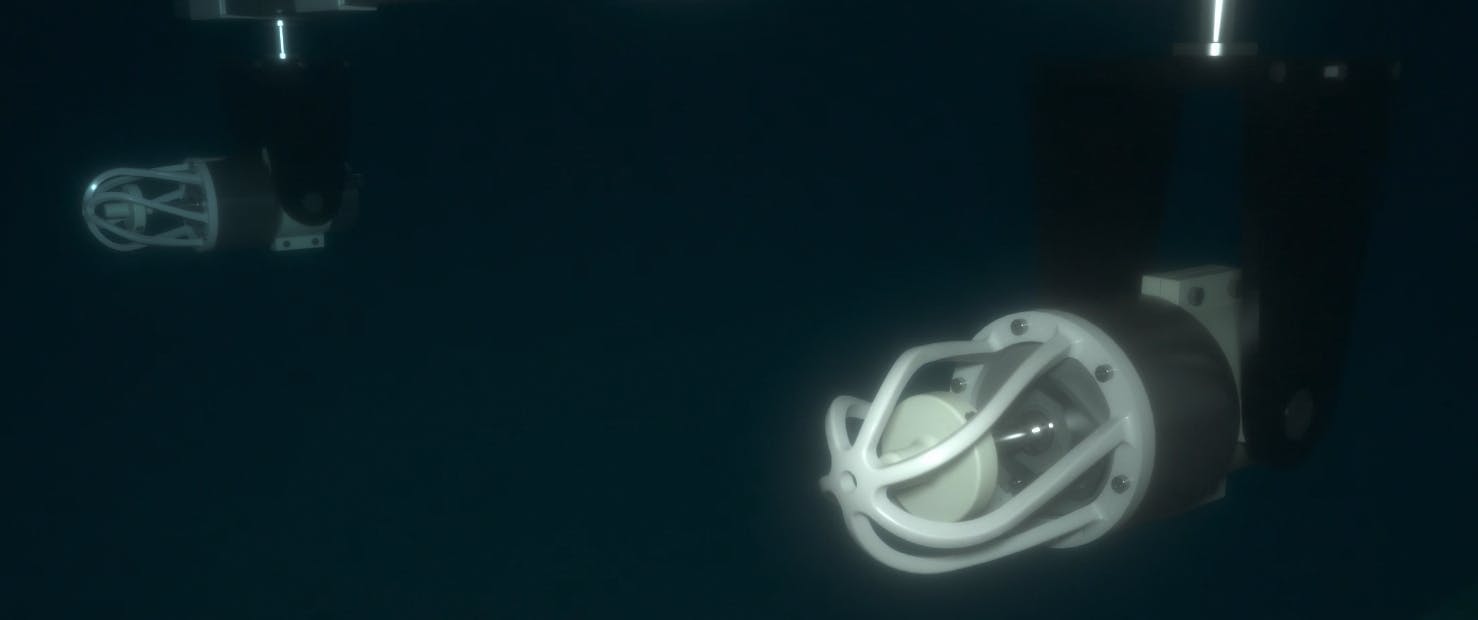

To address these challenges, FORCE Technology AS has developed the FiGS (Field Gradient Sensor) technology, a high-sensitivity sensor designed to monitor CP systems without the need for physical contact. This cutting-edge solution measures electric field gradients in the surrounding seawater, providing a more accurate and comprehensive assessment of the structure’s CP system.

**How FiGS Enhances Monitoring Efforts**

The FiGS technology leverages its high sensitivity to detect even the smallest variations in electric fields caused by current flow from the anodes to the metal surface. This precision enables early detection of potential issues such as coating damage or unexpected anode depletion rates, allowing operators to proactively address these problems before they escalate. By providing a detailed map of the CP system’s performance, FiGS empowers operators to enhance overall safety and longevity of subsea infrastructure.

**Operational Efficiency: The FiGS Advantage**

Traditional CP monitoring techniques are often slow and labor-intensive, involving extensive manual inspections. In contrast, FiGS surveys are faster and more efficient, utilizing ROVs or autonomous underwater vehicles (AUVs) that can travel at speeds of up to 6 to 8 km/h along pipelines. This increased speed reduces downtime and minimizes operational risks by allowing data collection from greater distances, even in challenging deepwater conditions.

Moreover, the FiGS technology integrates seamlessly with pipe tracking systems, effectively operating on various pipeline types including buried, trenched, or rock-dumped pipelines